You have questions about Brother DTG. We have the answers.

Find out everything you need to know about direct to garment printing and if it makes sense for your business.

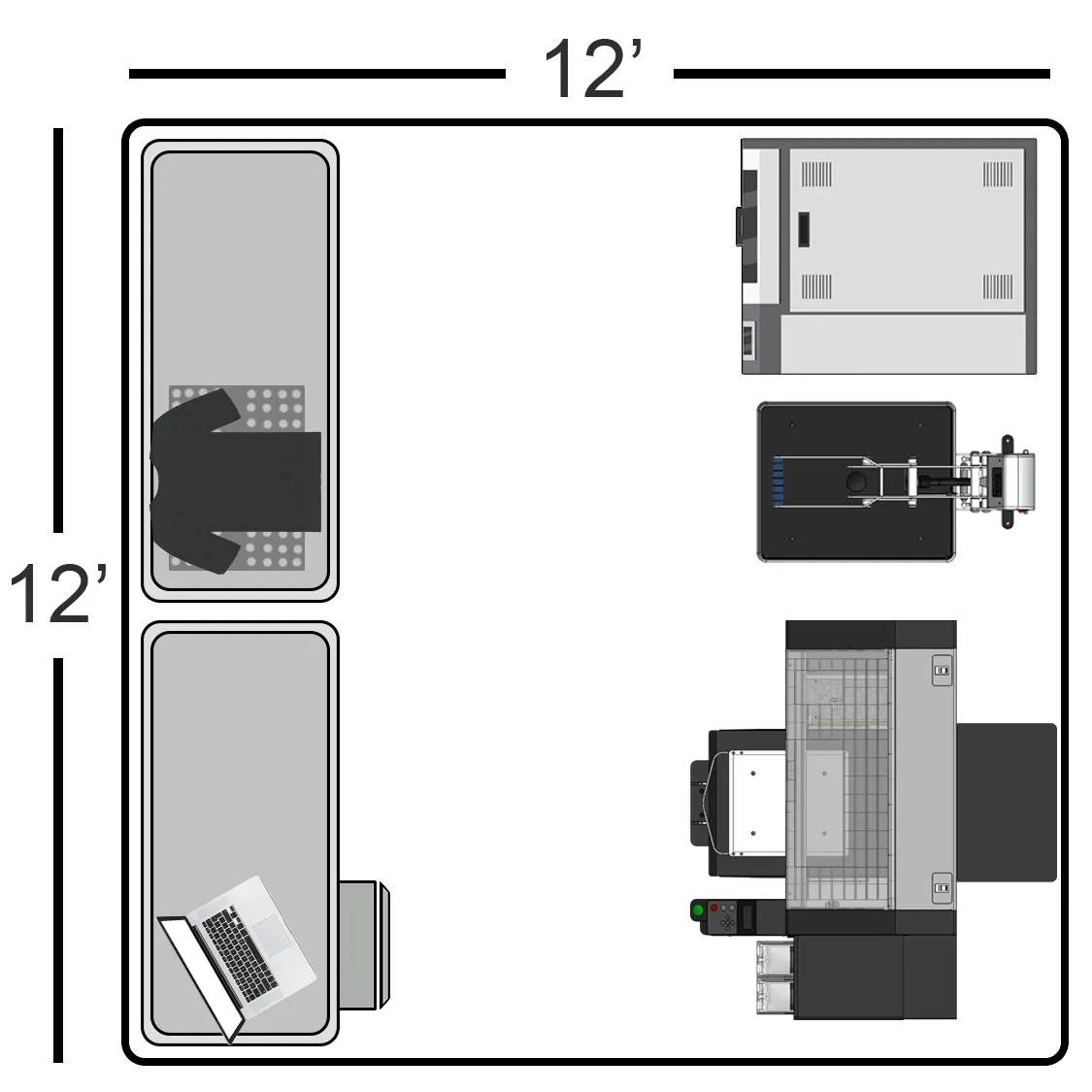

You can set up your GTXpro printing station in a spare room, garage or just about anywhere that's convenient.

The Dimensions of the printer are 55” (W) x 51” (D) x 21” (H) or 1400mm x 1290mm x 535mm). You'll also need a heat press and automatic pretreater. The sizes of these pieces vary depending upon the manufacturer you choose. However the average user can run a full set up in a 12' x 12' room.

See the floor plan graphic for a suggested room set up.

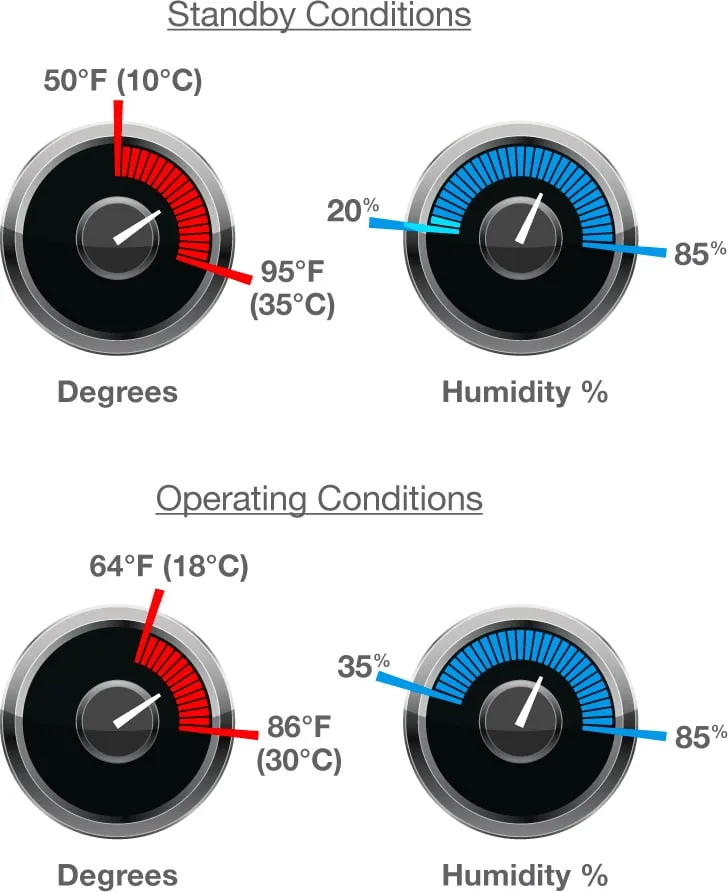

The room that the GTXpro printer is located in should be a clean, climate controlled room.

Temperature ranges should stay within 50 degrees F (10 degrees C) and 95 degrees F (35 degrees C) and relative humidity between 20% to 85%. When printing, it is recommended to be with the 64 degrees F (18 degrees C) to 86 degrees F (30 degrees C) and relative humidity between 35% to 85%.

Items with open, porous fibers like 100% cotton are ideal. Other items that are not treated or sealed, such as stone coaster, natural wood, raw leather and other items may allow the inks to bind to them as well.

New substrates should be tested before going into production.

GTXpro print heads have a large print head-to-substrate gap that makes it easier to print over zippers, seams, pockets and more.

This allows for doing wrap around prints on t-shirts, printing over pockets or zippers on hoodies and even over eyelets on shoes. While other printing methods require the substrate to be flat to get the proper off-contact, the GTXpro print head never touches the substrate.

The simple answer is no.

The GTXpro printer has built in maintenance procedures and tools that allow the printer to sit idle for multiple days. A highly advanced maintenance station incorporates wetting capping stations and a white ink circulation system.

The GTXpro printer uses Innobella Textile waterbased, pigment inks which can cure quickly.

These inks need to be cured either using a heat press for 35 seconds at 356 degrees F or a dwell time of approximately 2 to 3 minutes in a conveyor dryer / box at 320 degrees F.

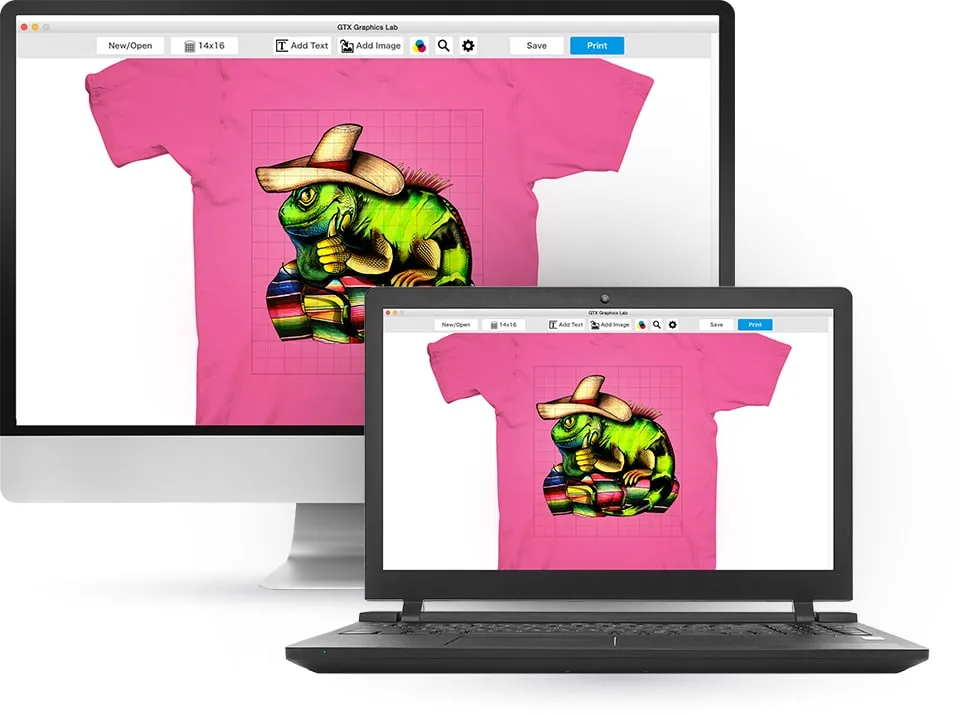

The GTXpro printer can work on either a PC or Mac operating system. Users can print directly from their favorite graphic design software using the GTX print driver.

Brother also provides its own software, GTX Graphics Lab, that allows users to layout their designs, apply artistic effects and send them directly to the GTX printer.

Supported operating systems: Windows 8.1(64 bit), Windows 10(64 bit), Mac OS® 10.14 Mojave, macOS 10.15 Catalina.

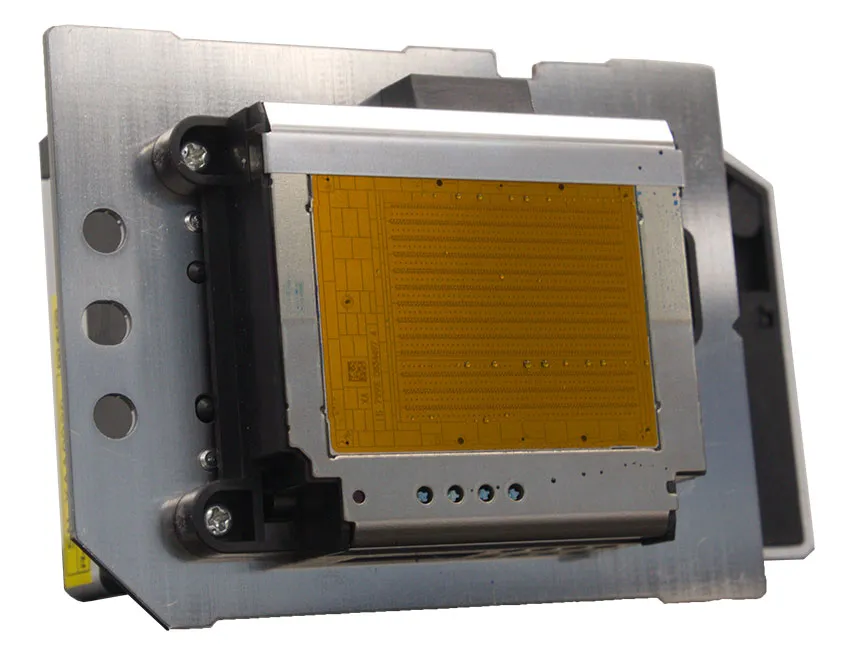

A print head is the component that jets tiny drops of the different colors of ink on to the substrate to recreate the artwork that is being printed.

The GTXpro printer uses two piezo print heads to jet the CMYK and white inks on to the substrate. Only a small number of companies in the world manufacture print heads. Brother is one of them and is the manufacturer of the GTXpro print head.

GTXpro is an industrial direct-to-garment printer. Many of the maintenance procedures are automatically performed for the users daily by the built-in features as long as the printer remains powered on.

Innobella Textile inks provides the GTXpro printer with a large color gamut to reprint your customers artwork. Brother also created a new pretreatment formula to work with the Innobella Textile inks that makes it easier to print on more colors of garments. Innobella Textile inks have been tested and certified to be eco-friendly.

The GTXpro printer is the fastest printer that Brother DTG has ever manufactured.

The print time of a design will vary depending on the size of the design and whether it using white ink or not. Watch the video to see a 11” x 11” design printed with CMYK+White ink.

To speak with a DTG Specialist to find out the print time on one of your designs click here.

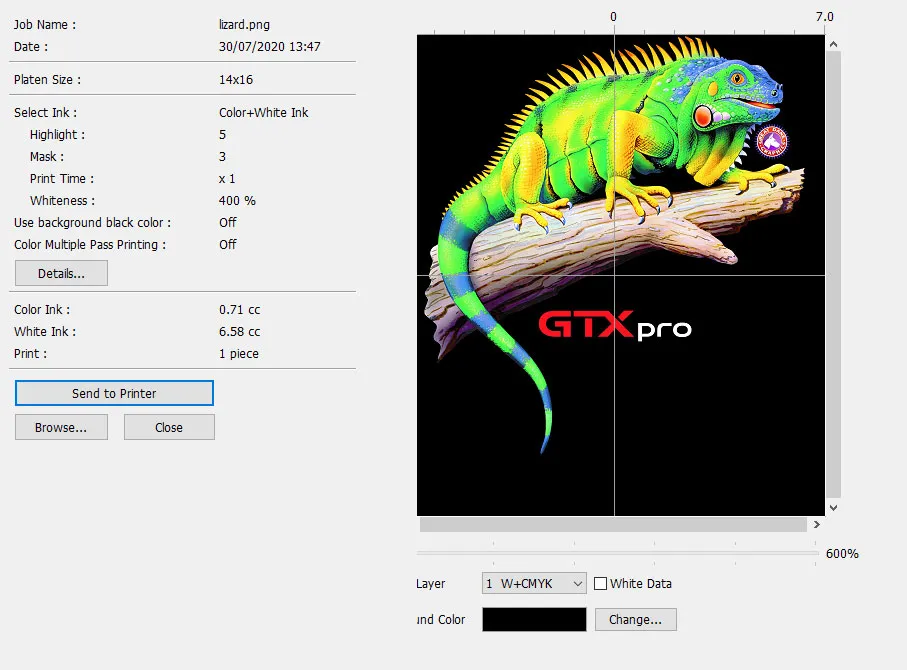

Similar to how the print time of a design can vary depending on several factors, the cost per a print can also.

The cost of the print is based on the size of the design, whether printing CMYK or CMYK+White inks, the colors in a design and the cost of the consumables (ink and pretreatment). When using the GTXpro print driver, the operator can create an .ARXP file that will let you know the amount of ink used prior to printing the design. See an example of an ARXP file.

The washability of a properly cured GTXpro print should be very similar to that of a properly cured, waterbased screen printed shirt.

The Innobella Textile inks have been tested by the AATCC to provide a washability of 4.0 or greater.

The GTXpro print driver can be installed on both PC and Mac operating systems.

The PC operating system should be Windows 8.1 (64bit) or Windows 10 (64bit). The Mac operating system should be macOS® 10.14 Mojave or macOS 10.15 Catalina.

Screen printing and dtg printing are both viable methods of decorating garments.

Screen printing typically requires more upfront work (i.e. separating artwork, creating screens for each color in the design, registering the screens on the press,…) and tends to be a better decorating technique for larger runs or designs with a limited number of colors.

Screen printing is not ideal for printing over seams, zippers, pockets and other items that make a garment not flat.

Unlike traditional garment printing, DTG printing jets ink directly on to a substrate without touching the garment and prints higher detail images with limiting the number of colors in a design.

DTG printing is designed to handle short to medium size runs; as well as printing photographic quality.

Pretreating is the process of preparing a garment for printing with white ink that utilizes pretreatment to prevent the absorption of it into the fibers.

The pretreatment fluid creates a chemical barrier on the garment that causes a chemical reaction when the white ink touches it that gels the bottom of the ink and allows it to sit on the top of the fibers to create a good underbase to print the CMYK inks on.

Users typically apply the pretreat fluid to a garment using an automatic pretreater get uniform coverage and the proper amount.

The pretreated shirt is then cured on a heat press for 35 seconds at 356 degrees F with heavy pressure prior to being printed.

Additionally, some users will pretreat a garment that is being printed only with CMYK inks when printing on polyester, blends or cotton garments as it makes the colors pop more.